Material Grade

Aluminium 6061

Specifications

| Standard | ALUMINIUM 6061-O |

| UNS | A 96061 |

Mechanical & Physical Properties

| Density | 2.7 g/cc |

| Melting Point | 582 °C - 652 °C |

| Tensile Strength | Psi-18000 MPa-124 |

| Yield Strength (0.2%Offset) | Psi-8000 MPa-55.2 |

| Elongation | 25 |

Chemical Composition

| Aluminum 6061 | |

| Al | 95.8-98.6 |

| Cr | 0.04-0.35 |

| Cu | 0.15-0.4 |

| Fe | Max 0.7 |

| Mg | 0.8-1.2 |

| Mn | Max 0.15 |

| Zn | Max 0.25 |

| Si | 0.4-0.8 |

| Ti | Max 0.15 |

| Other, each | Max 0.05 |

| Other, total | Max 0.15 |

Material Notes:

Aluminum composition calculated as remainder. Information provided by Alcoa and the references. General 6061 characteristics and uses: Excellent joining characteristics, good acceptance of applied coatings. Combines relatively high strength, good workability, and high resistance to corrosion; widely available. The T8 and T9 tempers offer better chipping characteristics over the T6 temper.

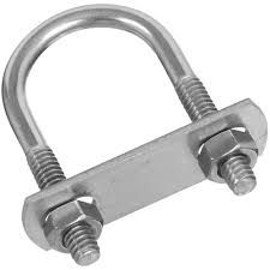

Uses: Aircraft fittings, camera lens mounts, couplings, marines fittings and hardware, electrical fittings and connectors, decorative or misc. hardware, hinge pins, magneto parts, brake pistons, hydraulic pistons, appliance fittings, valves and valve parts.Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||